Second Year

Week 10

So now we get to the hardest thing that has been done on Sheer. Harder then painting the hull or any other task. The new keel that was put on the Col 40 was a fin keel with a narrow and deep. Lead fills the front and I am pretty sure extra lead was added after the first ones were built because I have some plans for the lead installation with modifications for an extra 800-1000 lbs. The aft end is just air and it leaves a structural problem. The bottom of the keel slopes up from back to front. When the boat is on the hard it is usually blocked under that point as well as under the lead farther forward. There is no real structure above the keel end to take a load and when I first pulled Sheer there was a crack formed at the bottom of the keel.

In the first pic of Sheer right after she was hauled you can see the keel end all the way down. Notice the prop shaft way up, there is nothing but air under it all the way to the keel bottom.

Sheer after hauling at Napa

Here is the inside look after we cleaned the pit out. See week seven year one for more. The top of the engine mounts is level with the prop shaft. This will give you an idea of how deep the hole is, hard to show photographically. The bulkhead to the right is the back of the lead. the hunk of iron in the second pic is the old exhaust.

The Bilge Pit

Bilge Pit from Farther Out

So what to do about this. I did not like that deep a bilge, as it is underneath the engine anything that goes into it is lost if not forever at least until the engine is hauled out next time. It is almost impossible to clean.

I decided I wanted to add fibreglass, put in a bulkhead and if possible make a water tank in the keel. Here is where the hard part starts, to add fibreglass the old surface had to ground and cleaned. I dislike that kind of work in fibreglass but I was prepared to go at it but---- there is no way for my ancient and stiff and age enlarged old body to get down there. Eric was prepared to supervise but he is even more crippled up and inflexible then I am as well as having being 3-4 inches taller than me and shoulders that would stick in any attempt to go in head first. So Stu from 8 boats down volunteered. He wanted to learn a little more about fibreglassing.

So with Eric supervising, Stu got into the bilge with grinder, air disk sander and huge vacuum cleaner, then full respirator mask and 5 gallons of Isothallic resin and reams of matt and roving. So what do you get for a week of dirty hot close in work? You get the bulkhead here with many layers of fibre glass on it and on the walls of the bilge and also behind the bulkhead. It doesn't look much different but it is structurally much improved.

New Bilge and Bulkhead

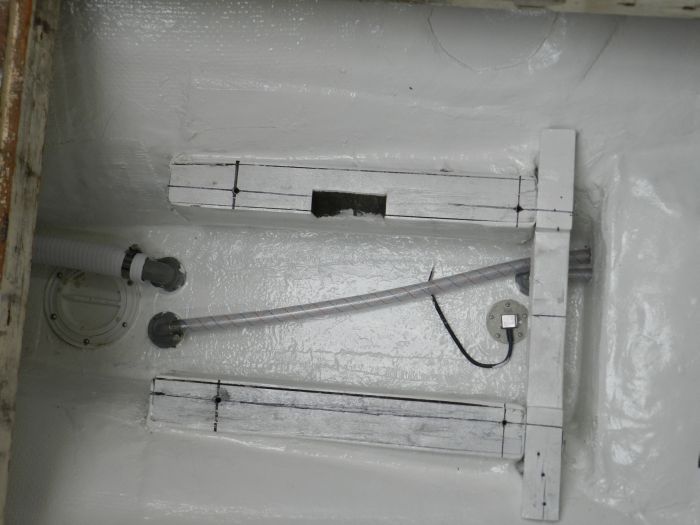

The pipe that runs through what will be the new water tank is to carry bilge water through to what is now going to be the bilge behind the bulkhead. The water used to just run down into the bilge but it is now stopped at the front of the tank. Rather than have it fill up there until it could run over the top of the tank I put this fibreglass tube through the tank and epoxied in place. Tom made a pattern and I rolled out a lid for the water tank on the laminating table and cut it to shape. I then painted the inside of the tank and lid with something called Amerlock 2, a paint made to be safe for potable water on the inside of tanks. Note the old mount for a depth sounder transducer on the right. It cot cut off and snaded down right after this pic was taken.

Roughed out Water Tank Lid

Water Tank Painted

So then the holes got cut in the lid for an inspection hole and the various fittings got installed, tank gauge, vent water pick up and fill tube. At the back of the bulkhead I filled it in with foam and the fibreglassed over the top of the foam. There is a flat spot for a bilge pump there and the manual bilge pick up will go there also. Then the whole area got primed and bilgecoated.

New bilge

Finished Tank

It took months over two winters to think this through and get it done. My goal was to get the tanks done in November, first thing. They were done in April.

Next